Considered until recently a niche segment, that of compact full electric wheel loaders today represents a growing business in the agricultural mechanization sector thanks to their ability to interpret the potential of electrification well in the context of the energy transition process pursued by the European institutions

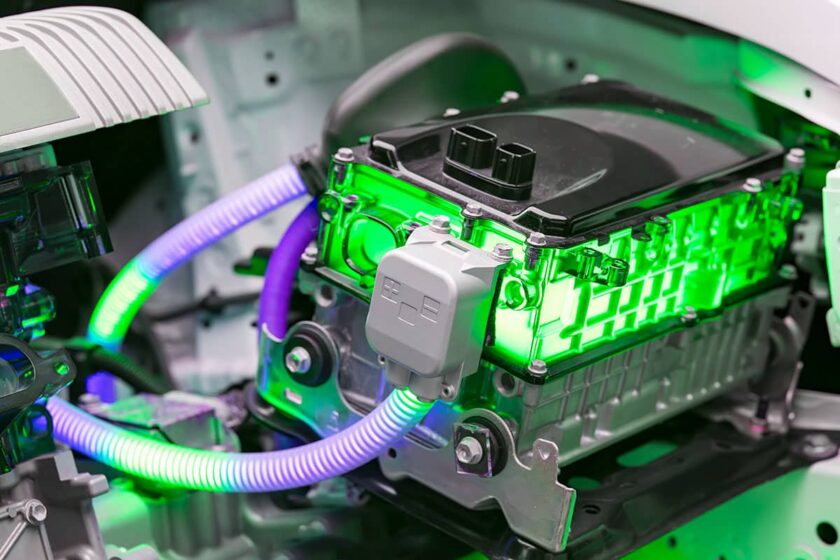

The electrification of compact operating machines with power ratings below 50 kilowatts, approximately 70 horsepower, is one of the main objectives advanced by the industrial segment in an energy transition perspective. This performance class currently allows to balance the actual advantages of environmental sustainability with operating situations suited to the needs of users in terms of performance and working autonomy.

A balance that is particularly interesting in the application areas related to agricultural and construction activities carried out using compact machines, from excavators to wheeled and tracked loaders to telescopic handlers and forklifts. All machines that often see their activities develop on the basis of cyclical load jobs, always operating at a very short range. Two limitations induced not so much by the performance of electric motors as by the power density of batteries, currently approximately 23 times lower than that proposed by diesel.

Full electric wheel loaders, unexpected protagonists

It follows that to ensure that an electrically powered agricultural machine has the same autonomy as a similar thermally powered model, a storage volume 23 times larger than the diesel tank would be needed, a ratio that, as power and therefore energy consumption increase, ends up causing the volumes and masses of the batteries to exceed the volumes and masses of the machine itself. These are problems that could be overcome in the future by the evolution of storage systems, but which today contribute to limiting the use of full electric machines to specific segments.

Municipal maintenance, for example, rather than light company movements and, in the agricultural sector, livestock applications. It is no coincidence that company and livestock maintenance represent the operational focuses that electric compact loaders used in the agricultural sector look at, vehicles that have only recently been introduced to the market but are constantly growing in terms of turnover.

ùAccording to estimates by industry analysts, this should in fact go from 100 million euros in 2023 to 150 million euros in 2030, low numbers in absolute terms but harbingers of an average growth rate of around six percent per year that could increase rapidly if the main player in the sector, the German group Wacker Neuson with its Kramer and Weidemann brands, were joined by other manufacturers as the British Jcb recently did. In the following pages, two in-depth analyses of the products available today.

Title: Full electric wheel loaders, a growing business

Translation with Google